- Home

- Products

- Elementary

- Boride Powder

- 3D Printing Powder

- Sulfide Powder

- Oxide Powder

- Carbide powder

- Nitride Powder

- Silicide Powder

- Hydride Powder

- Telluride Powder

- Selenide Powder

- Stearic Acid Series

- Phosphide Powder

- Nanoparticles

- Metal Alloy

- MAX Phase

- Lithium Battery Anode

- Surfactant

- Molecular sieves

- Concrete Admixtures

- News

- Answers

- Contact

- About

News

- 0

- 0

3D printing martensitic steel technology breakthrough can print any shape car parts without defects

If you are looking for high-quality products, please feel free to contact us and send an inquiry, email: brad@ihpa.net

According to reports, researchers from Texas A & M University and AFR have developed a technology for defect-free metal 3D printing of martensitic steel parts. Compared with similar steels, martensitic steels are more reliable and more cost-effective and are used in aerospace, automotive, and defense industries.

Although sturdy steel is widely used, it is usually expensive. The only exception is martensitic steel, which costs less than one dollar per pound and has a relatively low cost. They have also developed a 3D printing framework that can print these hard steels into flawless objects of any geometry.

What is martensitic steel?

For thousands of years, metallurgists have been carefully adjusting the composition of the steel to enhance its performance. To this day, there is a product called martensitic steel that stands out in its steel category because of its higher strength and more cost-effectiveness.

Steel is a material smelted from iron and carbon. Martensitic steel is manufactured by high-temperature quenching. This sudden cooling process restricts the carbon atoms to the iron crystals, giving martensitic steel its unique strength.

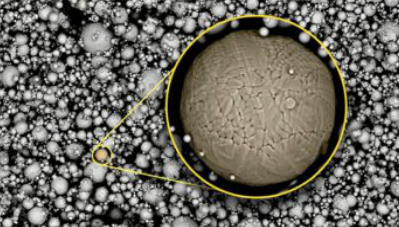

△ Martensitic steel powder for 3D printing. The picture shows an enlarged view of the steel powder.

The industry has a high demand for hardened steel, but its price is too high. An exception is a martensitic steel, which has a relatively low cost, less than one dollar per pound.

Martensitic steel is very suitable for the fields that need to manufacture high-strength, light-weight parts without increasing costs, such as aerospace, automotive, and defense industries.

Technology improvement 3D printing high strength defect-free martensitic steel

To have multiple uses, it is necessary to assemble martensitic steel, especially a type called low-alloy martensitic steel, into objects having different shapes and sizes according to specific applications. Additive manufacturing (commonly referred to as 3D printing) provides a practical solution. Using this technology, a single layer of metal powder can be heated and melted in a pattern by using a high-energy laser beam to build complex parts layer by layer. Connect and stack all these layers to print out the final 3D printed object.

However, 3D printing of martensitic steel using lasers can cause defects in the form of pores in the material.

To solve this problem, the research team had to start from scratch and find out the laser settings that could suppress such defects.

In the experiment, first, an existing mathematical model was used to predict the melting of a single layer of martensitic steel powder under different laser settings. Next, by comparing the observed defect types, number, and model predictions, they improved the printing framework. After many iterations, their structure can make predictions more accurately. The researchers said that this method does not require additional experiments, which saves more time and effort.

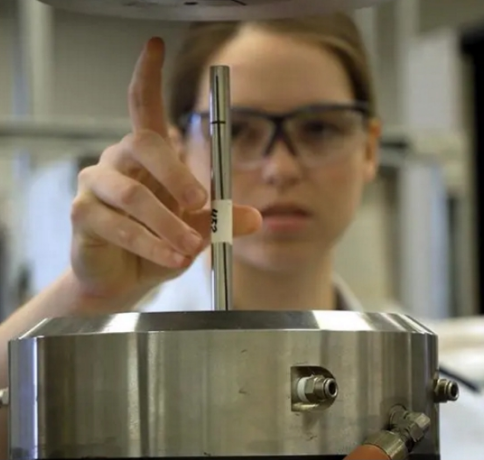

△ The US Air Force Research Base conducted studies on the printed samples such as porosity, mechanical strength, and impact toughness, and the display's mechanical properties were excellent.

Although the initially developed process was for martensitic steel, they have made the technology versatile enough so that the same 3D printed pipeline can also be used to build complex objects from other metals and alloys.

This is an essential development for all types of metal additive manufacturing industries. Whether it is a simple part like a screw or a more intricate part of turbines such as landing gear or a gearbox, it will become more precise in the future To meet the needs of different industries.

This innovative prediction technology will shorten the time to evaluate and find the appropriate printing parameters for martensitic steel. However, testing the possibility of all laser settings and evaluating which may cause defects is very time-consuming and sometimes impossible. Yet, a quick and straightforward step-by-step process was developed by combining experiments and modeling to determine which setting is most suitable for 3D printing martensitic steel.

Inquiry us

PREVIOUS NEWS

What is P-test-butyl Benzoic Acid

NEXT NEWS